Molds for a concrete block making machine in 30 days!

Molds for concrete making machines

Stages of the moulds manufacture at the Mustafa Yontar plant

Development of drawings

The development of drawings for a future matrix and swage taking into account all the requirements of your concrete block machine manufacturer. Consideration of drawings and production dates.

Plasma cutting

A sheet of high-quality steel, of a certain thickness is placed on a specialized machine with a plasma cutter, where the main parts of the swage and the matrix are cut out. The entire process is fully automated.

Coordinate check

The matrix is placed on a coordinate machine on which a sensor is mounted, which will find all deviations from set values in all cells of the matrix.

Milling

The cut plate of the swage is treated on CNC machines, elements for fastening the plates of swages to the swage are made in the same place. At the same time, the matrix is placed on a milling machine in the adjacent workshop, where the milling to a specified height and then grinding are performed.

Welding works

Then, fasteners are welded to the matrix, technological holes are drilled in the fastenings in order to fix the matrix to the concrete block machine. The fastening elements are welded to the plates of the swage, then the fastening elements are welded to the swage. All welding joints pass the UT test.

Assembly

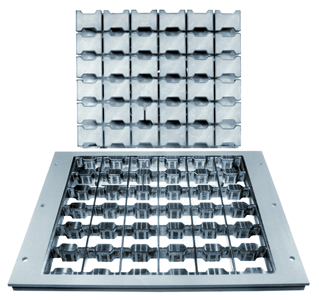

The matrix and the swage are installed in the coordinate machine, where the swage will be placed in the matrix, the following checks will be carried out: no distortion, no squeaks and scuffs.

Painting

Plasma cutting of the sockets of the future matrix

Checking the matrix cells on the coordinate machine

Milling the matrix to the given dimensions

Finishing of plates of punches

Welding works

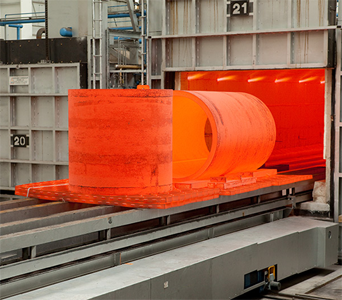

Heat treatment of blanks

Checking the geometry of the mold

Punch paving slab coil

Painting shop

Warehouse of molds for concrete block making machine

Matrix and punch for concrete block making machine