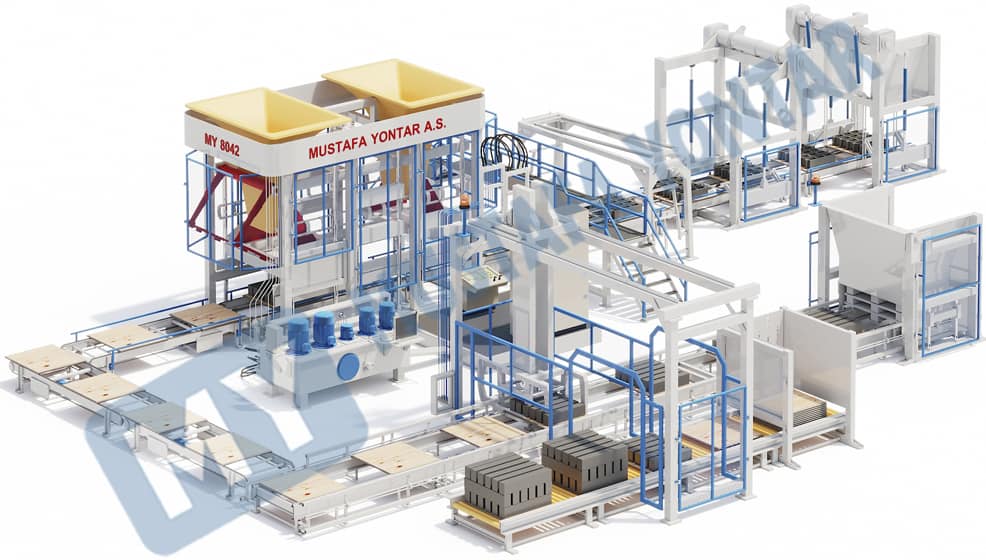

MY 8042 block machine - the choice of professionals

Dimensions 18000х6750х5100 mm.

Performance: 211 pallets per hour.

Size of the process pallet 1500х1300х50 mm.

Number of products on a pallet:

Paving slabs 200х100х60 mm. - 66 pcs. (1,32 m2)

Block 400х200х200 mm. - 18 pcs.

Kerbstones 1000х300х150 mm. - 6 pcs.

Kerbstones 1000х200х80 mm. - 12 pcs.

Vibro table size 1400х1260 mm.

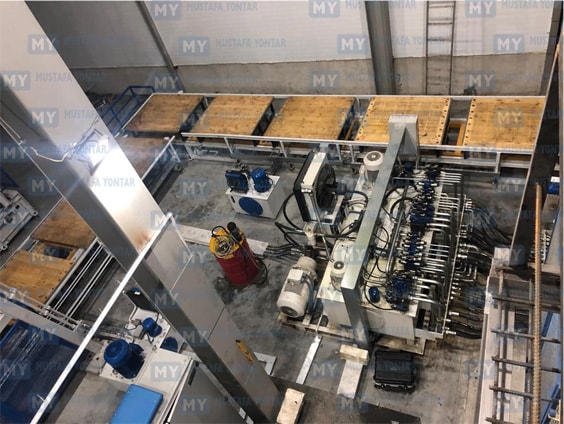

Number of bottom vibrators 6 pcs. (240 КN).

Number of top vibrators 2 pcs.

Volume of a hopper for concrete mix 2300 l.

Maximum height of products 500 mm.

Minimum product height 40 mm.

The volume of hydraulic installation with a robot 1600 l.

Forming modes Automatic, manual.

kerbstones

1000.300.180 mm 13000 pcs.

1000.300.150 mm 13504 pcs.

1000.200.80 mm 20256 pcs.

Paving slabs

200.100.60 mm 2228 m2.

200.100.80 mm 2000 m2.

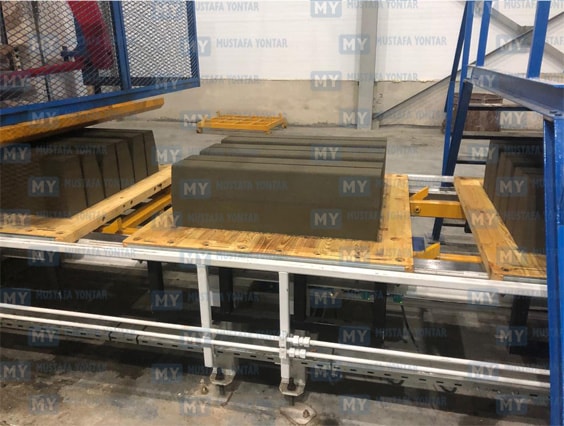

Blocks

400.200.200 mm 30384 pcs.

400.100.200 mm 53000 pcs.

Concrete block machine with one hopper for concrete

Elevator-accumulator of technological pallets (dry side)

Elevator-accumulator of technological pallets (wet side)

Electrical cabinet

Software

Mold

Optional equipment

Bunker facing layer

Сuber

Conveyor for euro pallets

Washing system

Finger car

MY 8042 - Fully automatic concrete block making machine, based on the principle of hydraulic pressure and mechanical vibration. It refers to the type of single row machine.

The powerful construction, weighing 60 tons, built with a considerable margin of safety, as well as the use of high-quality electronic, hydraulic and mechanical components of leading European brands such as Bosch-Rexroth, Omron, Siemens, etc., make it possible to produce high-quality small-piece concrete products, such as: paving slabs, road and garden kerbs, wall blocks, gutters, etc.

MY 8042 - equipped with a powerful, divided vibrating table, consisting of three parts (240 KN) with forced cooling, which is fully controlled by an automatic control system based on SIEMENS / Omron electronics. In the menu of an enlarged touch screen, you can change the molding parameters, including the frequency of each vibrator and the amplitude of the vibrotable.

The MY 8042 concrete block making machine is delivered with one hopper, two conveyors and two elevators with hoppers, a pallet-paver robot with a conveyor of euro pallets, a measuring box equipped with an active agitator. Facing layer hopper, surface washing system, automatic system for transporting pallets to the steaming chambers (using the finger car) are optional.

The two-hopper system allows to produce products on different aggregates, which allows to reduce the cost of products. And also allows more economical use of the dye.

The line is perfect for those who need the machine with the highest performance and reliability, confirmed by 50 years of experience in the market of concrete block making machine manufacturers.

Variety of colors and shapes

Photo Gallery. Lipetsk 2019

Video