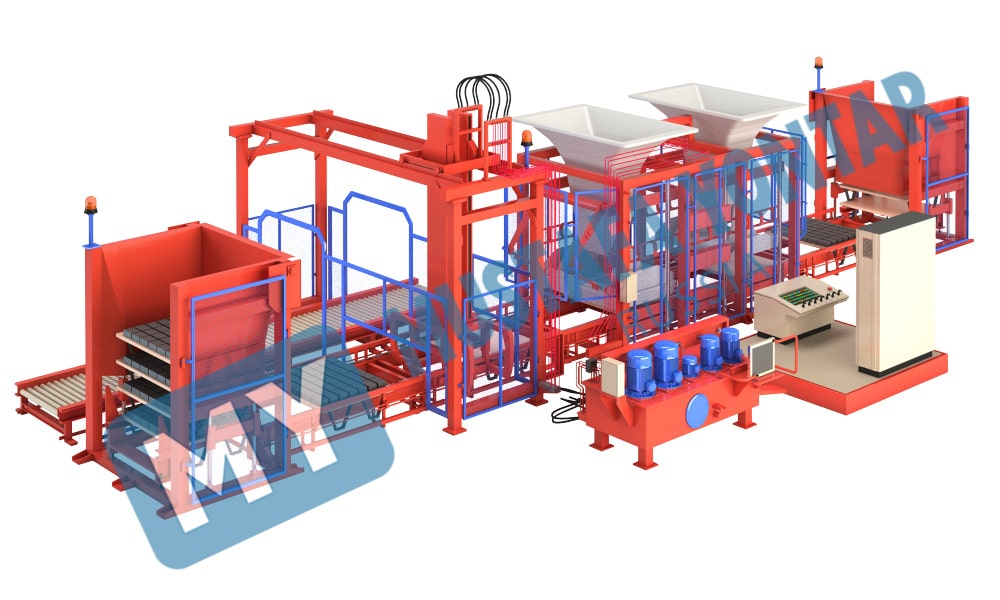

Concrete block making machine KPM 1025

Dimensions 10500х4350х3450 mm.

Performance: 125 pallets per hour.

Size of the process pallet 1330х950х45 mm.

Number of products on a pallet:

Paving slabs 200х100х60 mm. - 40 pcs. (0,8m2)

Block 400х200х200 mm. - 10 pcs.

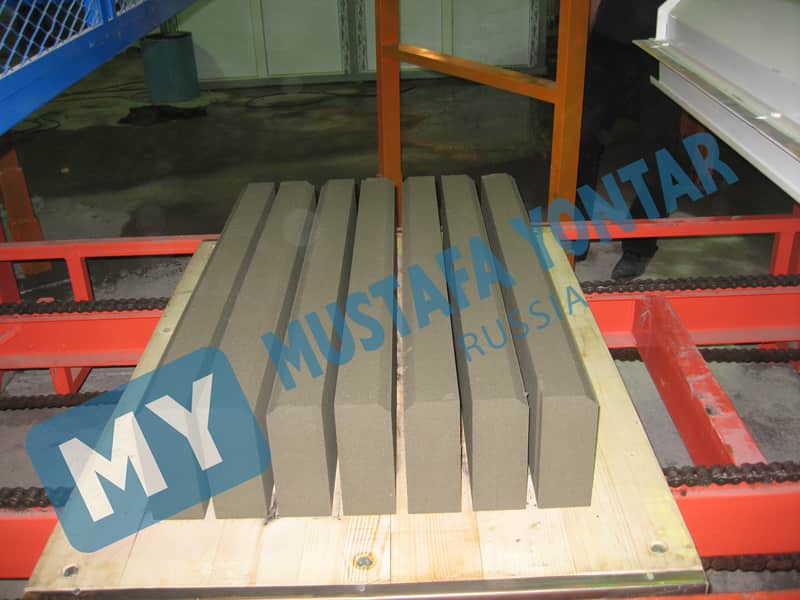

Kerbstones 1000х300х150 mm. - 2 pcs.

Kerbstones 1000х200х80 mm. - 6 pcs.

Vibro table size 1090х890 mm.

Number of bottom vibrators 4 pcs. (160 КN).

Number of top vibrators 2 pcs.

Volume of a hopper for concrete mix 1800 l.

Maximum height of products 300 mm.

Minimum product height 50 mm.

The volume of hydraulic installation with a robot 1000 l.

The volume of hydraulic installation without a robot 600 l.

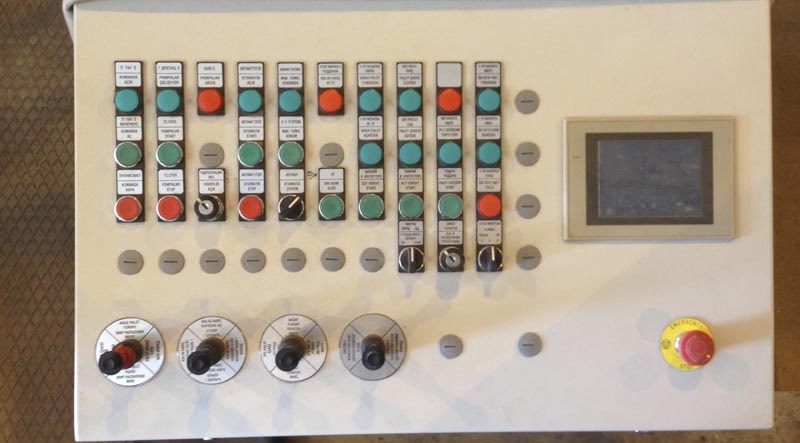

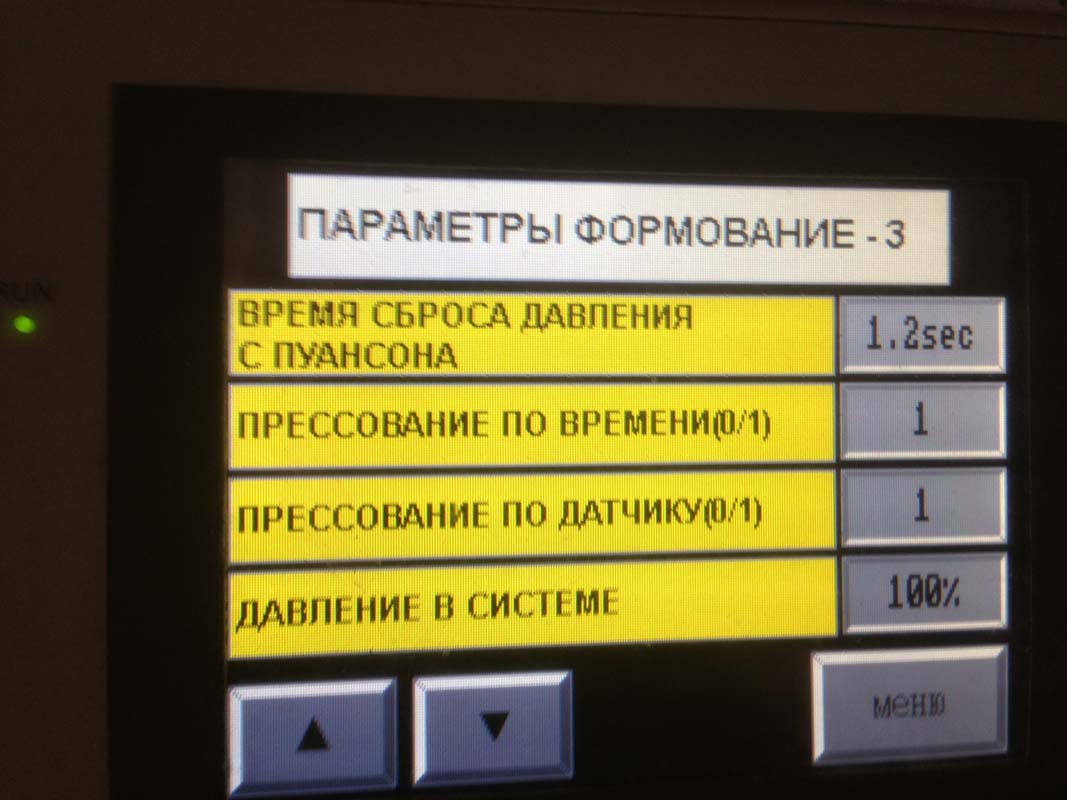

Forming modes Automatic, manual.

kerbstones

1000.300.180 mm 2000 pcs.

1000.300.150 mm 2000 pcs.

1000.200.80 mm 6000 pcs.

Paving slabs

200.100.60 mm 800 m2.

200.100.80 mm 750 m2.

Blocks

400.200.200 mm 10000 pcs.

400.100.200 mm 22000 pcs.

Concrete block machine with one hopper for concrete

Elevator-accumulator of technological pallets (dry side)

Elevator-accumulator of technological pallets (wet side)

Electrical cabinet

Software

Mold

Optional equipment

Bunker facing layer

Сuber

Conveyor for euro pallets

Washing system

КРМ 1025 is a fully automatic concrete block making machine operating on the principle of using hydraulic pressure and mechanical vibration.

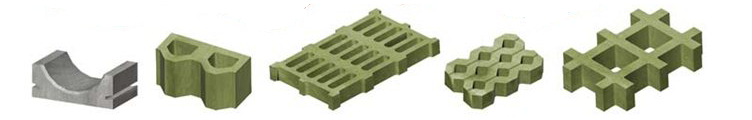

КРМ 1025 has a powerful construction weighing 20 -30 tons. The use of high-quality electronic, pneumatic, hydraulic and mechanical components allows to produce high-quality small-piece concrete elements, such as paving tiles, road and garden curbs, wall blocks, gutters, etc.

Unlike its preceding modification, КРМ 1025 has a fully automatic control system. It is equipped with a robot – a pallet-laying machine used for transferring the finished products to euro pallets, which significantly increases the production rate for all products.

Concrete block making machine КРМ 1025 is supplied with one or two hoppers, two conveyors and two storage elevators. The pallet-laying robot with the euro pallets’ conveyor can be supplied as an option.

A double-hopper system allows to produce units with different fillers, which allows to reduce the cost of the product and to use the coloring agent with higher efficiency.

The line is perfect for those who require a line with an average production rate and reliability confirmed by a 50-year experience on the market of the manufacturers of vibropresses.

Variety of colors and shapes

Photo Gallery

Video